Biomimetics of high performance protein fibers

We are employing a biomimetics approach to explore natural fibers that might serve as viable models for the manufacture of high performance and eco-friendly fibers, which could one day replace petroleum-based fibers like Kevlar. One such model is the protein fibers that are found within the defensive slime of hagfishes. These “slime threads” are similar to spider silks in their dimensions and mechanics, but they differ in a couple of important ways that make them excellent candidates for such a biomimetic project. We have published one study on the production of fibers using proteins isolated from hagfish slime threads (Negishi et al. 2012), and another in which we made fibers from a related protein, vimentin (Pinto et al. 2014). Collaborators on this project include Todd Gillis from the University of Guelph, Maikel Rheinstadter from McMaster University, and Laurent Kreplak from Dalhousie University.

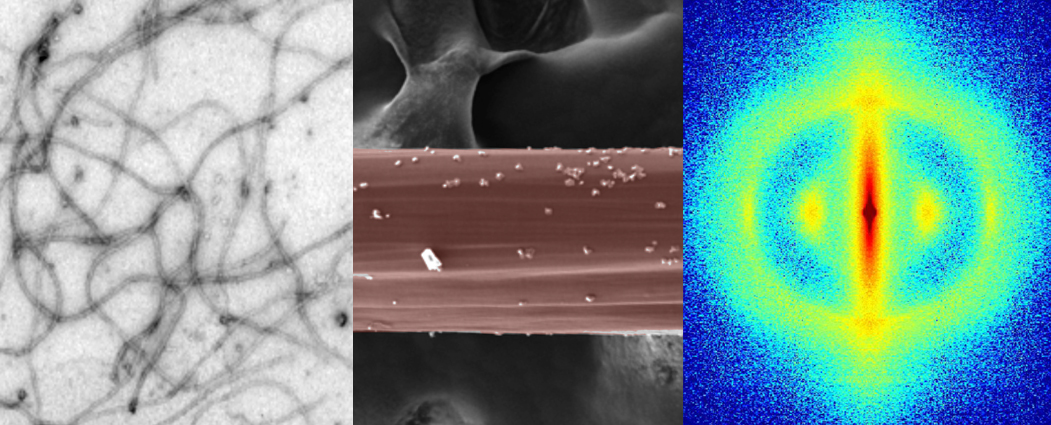

In a project headed by research associate Atsuko Negishi and MSc student Nicole Pinto, we produced fibrous materials from the intermediate filament protein vimentin, which is related to the proteins found in hagfish slime threads. Shown in the image to the left is an electron micrograph of vimentin proteins assembled into high aspect ratio 10 nanometer filaments, an EM image of one vimentin fiber, and an x-ray diffraction image of a stretched vimentin fibers (created by collaborators Maikel Rheinstadter and Fei-Chi Yang of McMaster University).

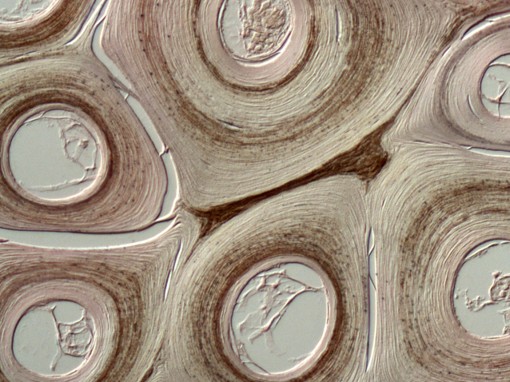

Our research has shown that hagfish slime fibers have tensile properties that rival spider dragline silks (see Fudge et al. 2010). Here, hagfish slime threads stained with the textile stain Congo Red show a range of colours in polarized light depending on how much they have been stretched (Fudge et al. 2003).

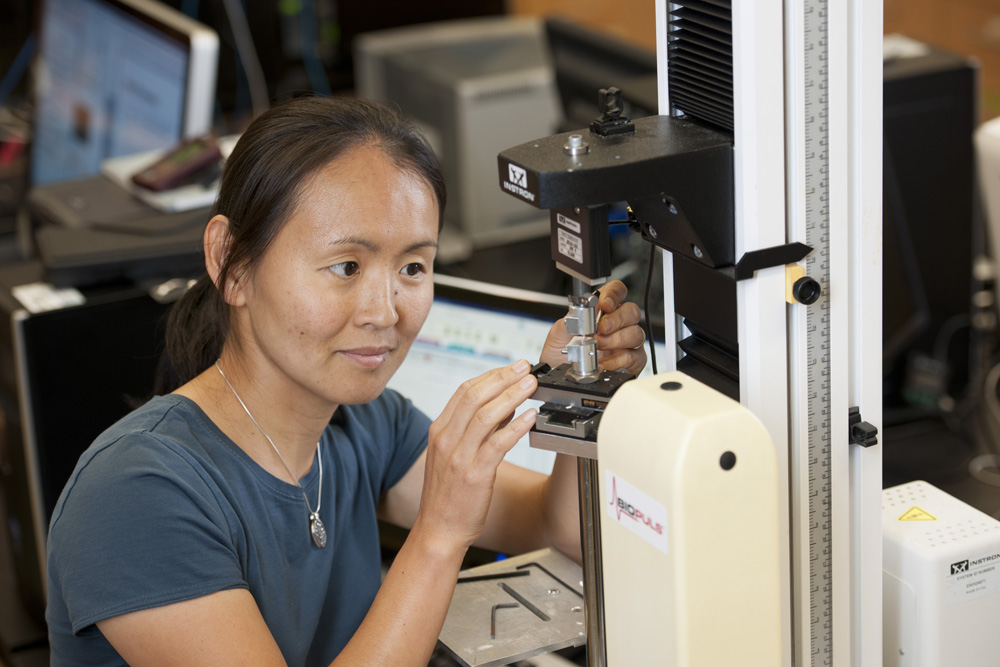

We evaluate the quality of natural and biomimetic materials using a variety of materials testing techniques. Here, research associate Atsuko Negishi conducts tensile tests on some of the biomimetic protein fibers she has produced using an Instron universal testing machine.

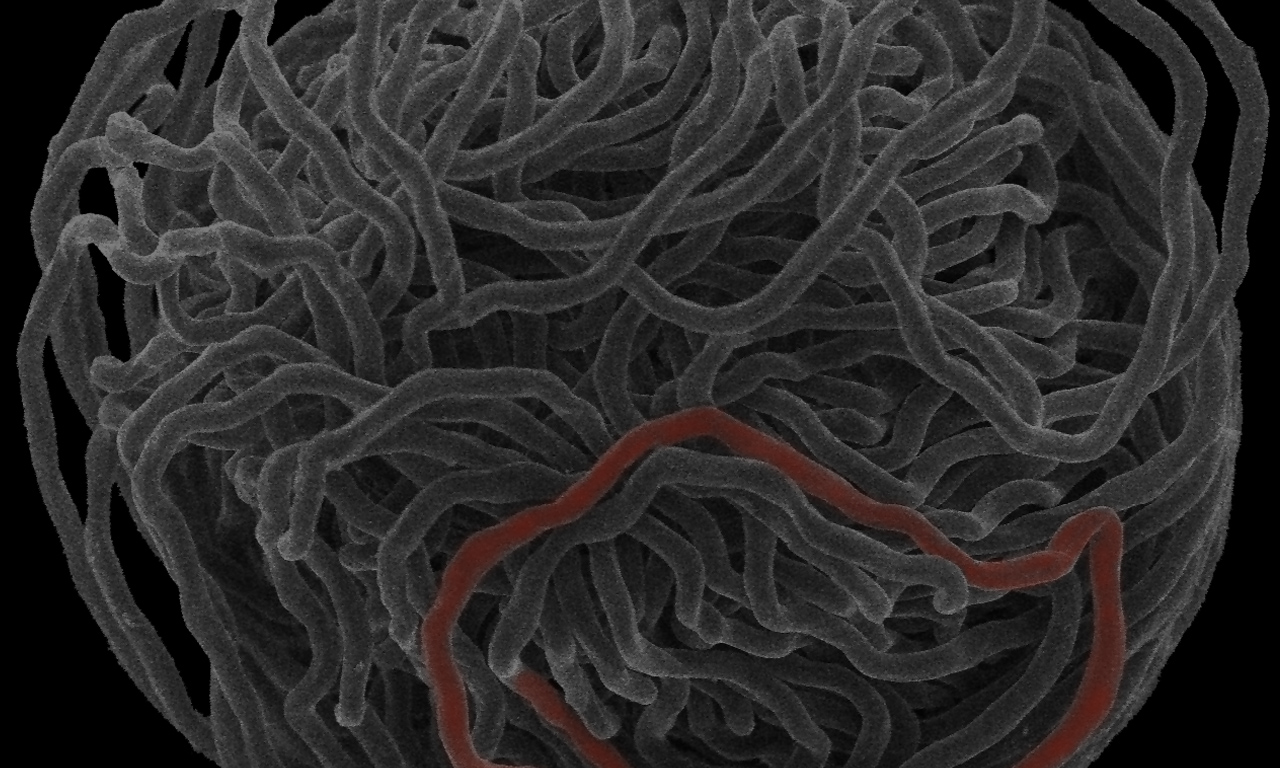

We have made fibers from solubilized hagfish slime thread proteins by allowing them to coagulate on a the surface of an electrolyte buffer and drawing fibers from the resultant film. For more information, see Negishi et al. (2012).

Other Research in the Fudge Lab